This year at the World Congress on Particle Technology (WCPT) students took part in a particle technology workshop designed especially for future engineers. The session, chaired by Mayank Kashyap from SABIC, focused on pressure and temperature swing adsorption technologies and cyclone separators.

Structured adsorbents and cyclone separators

The majority of commercial-scale adsorption units are packed columns, filled with carbon or zeolite adsorbents. In the first presentation of the student workshop, James Ritter, a professor at the Univ. of South Carolina (USC), described the advantages of using structured adsorbents. “Structured catalytic systems have been around forever,” said Ritter, “but they haven’t caught on for many commercial applications.”

According to Ritter, structured adsorbent systems have significantly lower pressure drop than traditional packed-bed systems and they produce higher mass transfer rates. In addition, they have better thermal management characteristics than packed beds. “These systems are ideal for high-throughput, faster or rapid-cycle pressure swing adsorption (PSA) or temperature swing adsorption (TSA) systems where gas velocity and heat transfer may be issues,” said Ritter.

However, these systems come with more manufacturing challenges than traditional packed beds; it is easier to fill a column with adsorbent beads than to design ideal structured packing.

In his presentation, Ritter reviewed ongoing R&D efforts that his research group at USC is pursuing. The group tested two types of structured adsorbents — Zeolite 13X and Catacel — in a bench-scale PSA process. They found that these two structured adsorbents easily outperformed beaded adsorbent in terms of feed throughput because structured beds have higher void space and lower packing density. For the same feed flowrate, your structured bed can be one-tenth the size, said Ritter.

Ritter’s lab investigated a third type of structured adsorbent with NASA funding. The average astronaut produces up to 1 kg of CO2 per day. To keep astronauts alive on deep space missions, NASA is looking for a pressure-temperature swing adsorption (PTSA) system that can remove up to 4 kg of CO2 per day from the space shuttle. Ritter and his research group first simulated the dynamic adsorption process and then performed bench-scale lab analysis using a Zeolite 13X Catacel structured adsorbent. Surprisingly, the lab analysis validated the simulation results and showed that it may be possible to use structured adsorbent for this application.

In the second presentation of the workshop, William Heumann and Thomas Cushing of Heumann Engineering described a method for approximating pressure drop and particle collection rates for a range of cyclone separators. Cyclones separate particles from a high-speed gas or liquid flow via rotational effects and gravity.

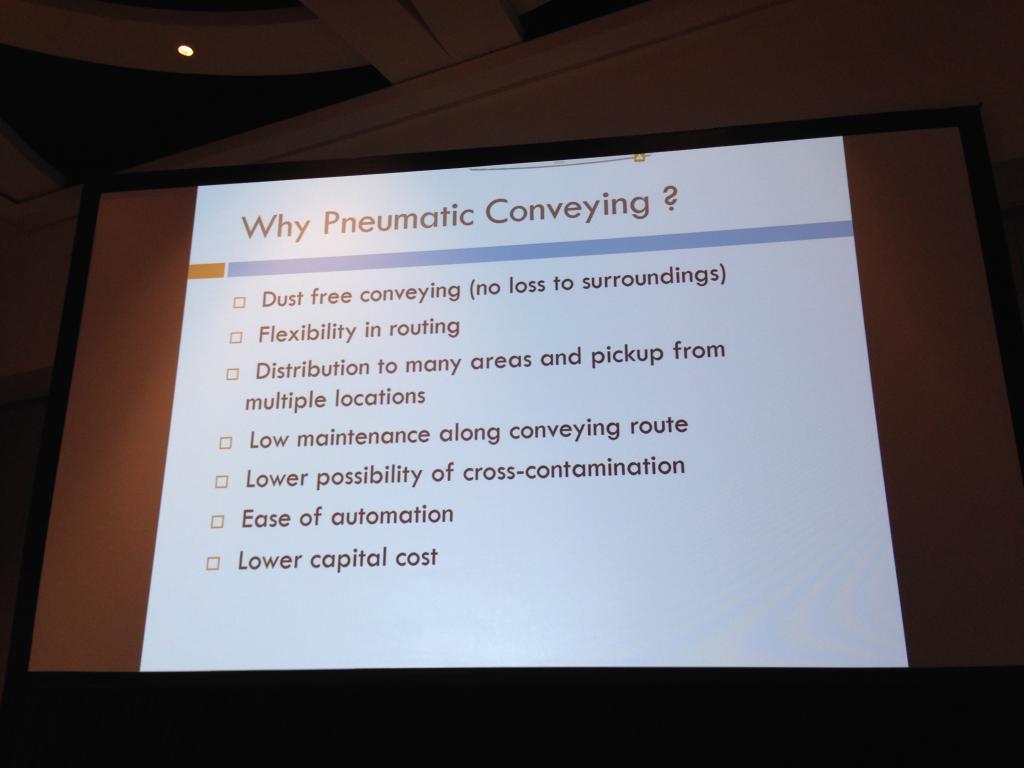

Solids handling and pneumatic conveying

The second half of the student workshop featured a session led by Shrikant Dhodapkar (The Dow Chemical Company) and Kerry Johanson (Material Flow Solutions, Inc.). Together, they gave attendees an introduction to the field of solids handling and processing.

According to Dhodapkar, 50% of products in the chemical industry are either sold as a solid or they have been in a solid state at some point in time. That makes solids handling extremely important to all chemical engineers.

Johanson’s portion of the presentation focused on characterizing particles and powders. He spoke about how the unconfined yield strength of a material will impact how the material flows in bins and hoppers. He described ratholing and stable bridging and how to look out for these issues in solids handling applications.

Have you ever wondered why a sandcastle is able to retain its shape? Johanson answered this question with a brief explanation of adhesive forces. These forces affect solids flowability in silos and other storage vessels.

Dhodapkar’s portion of the presentation gave attendees an overview of pneumatic conveying. His talk was filled with fun facts, as well as a wealth of information on dilute- and dense-phase conveying. For example, did you know that pneumatic conveying was used to transport the cement used to build the Hoover Dam?