More than 2 billion people don’t have access to clean drinking water. As the leading cause of hospitalization in emerging countries, germs in drinking water account for 1.2 million deaths every year. The world needs a solution to achieve U.N. Sustainable Development Goal 6.1: universal access to safe and affordable drinking water for all. But existing solutions are neither affordable nor accessible to the people who need them the most.

Existing filtration membranes — such as ultrafiltration, reverse osmosis, graphene, bromine resins, copper or silver materials, and other antimicrobial filters — are costly to manufacture. The resulting consumer products are sold for $40–$300, a price point that is too costly for low-income consumers in emerging markets. According to a Folia consumer survey, only 10% of these consumers are willing or able to pay $40 for a filter. However, these same consumers buy consumer health staples like soap and toothpaste, and collectively spend $3 trillion on groceries. An affordable water filter is needed at the same 20-cent mass market grocery pricing as soap, snacks, and SIM cards.

Folia Materials, a Boston-based small business, was formed to commercialize a coating technology, born from the work of their Chief Technology Officer, Theresa Dankovich. For her doctoral studies in chemistry at McGill Univ., Dankovich was asked to create a low-cost water filter using green chemistry and paper. The resulting silver antimicrobial paper is packaged like a coffee filter, kills 99.9999% of bacteria and 99.7% of viruses, and removes 99.99% of protozoa and 99.8% of iron.

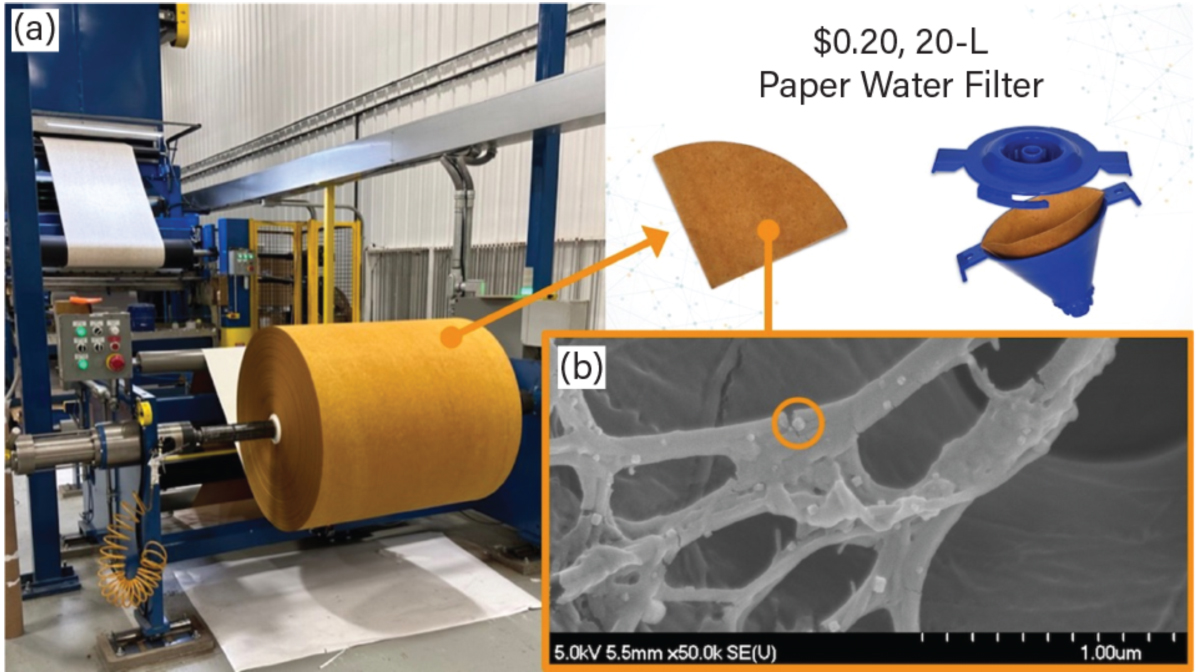

▲ (a) Folia’s silver-based coating can be applied to paper filters using standard industrial coating processes, yielding a water filter that costs just pennies. (b) The coating process forms metal nanoparticles ionically bonded to cellulosic fibers within the paper filter.

Funding from the U.S. National Science Foundation (NSF) allowed Folia Materials to scale the paper coating and manufacturing process from bench to industrial scale. Working at industrial partners’ manufacturing facilities, Folia has completed repeat manufacturing from raw materials through industrial paper coating and converting to finished packaged product at the pennies unit costs required for mass-market grocery products.

The fundamental technology is a food-safe, green-chemistry process that forms silver nanoparticles ionically bonded to cellulosic fibers. The company holds international patents on the industrial coating process and aqueous paper coating formulation, which consists of metal salts and catalysts that reduce the silver and bond it to the cellulosic fibers during the coating process. Manufacturing costs are minimized by using plant-based food ingredients as green chemistry catalysts and silver nanoparticles to minimize the amount of silver required, as well as by being a true drop-in solution for industrial paper and packaging supply chains, with no capital modifications required. The manufacturing process uses commodity inputs and standard industrial coating machinery and is therefore able to achieve the required grocery shelf price of only $0.20 for 20 L of safe drinking water.

The technology has many applications, each taking advantage of its key benefits: food-safe ingredients, pennies unit costs, and the high-volume manufacturing scale of the paper industry. The same industrial process is currently being used for the company’s microwave food packaging, where the metal converts microwaves into thermal energy to achieve better quality microwaved frozen food.

Subsidiary Folia Water Global (FWG) was spun out to focus on commercializing the Folia Water Filter as a mass-market grocery retail consumer health staple. Unilever and Aqua for All sponsored a market entry pilot into Bangladesh that proved product-market fit with 366,000 filters sold from 2,500 stores. FWG is currently expanding to 10,000 stores to attract a national consumer goods distributor, prior to international expansion through consumer goods master distributors.

“To address the global drinking water crisis, we need to support innovative, sustainable solutions that meet the needs and realities of local communities,” says Sarah Kalin, program manager at Aqua for All. “Folia’s water filter is affordable, effective, and easily accessible for the millions of people without access to safe water in Bangladesh. Aqua for All partners with FWG to help it scale and consolidate a sustainable business model that can grow within Bangladesh and beyond.”

This technology was supported by the NSF Small Business Innovation Research (SBIR) program.

This article was prepared by the National Science Foundation in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.