Sections

- The MOC review is the sum of many reviews

- The screening step

- Engage discipline representatives to perform discipline-specific reviews

- Engage discipline representatives to support assessment of replacement-in-kind vs. MOC

- In praise of slow MOC: Be cognizant of the good-fast-cheap triangle

- In closing

- Anecdote: Buyer Beware!

- Literature Cited

Management of change (MOC) reviews should not be do-it-yourself, even for small changes. Seek skilled specialists for all aspects of your MOC reviews.

One of the primary objectives of management of change (MOC) is to ensure that changes made to correct one problem do not introduce unintended consequences or new problems. MOC reviews are accomplished by considering the change from multiple perspectives rather than focusing narrowly on the problem at hand.

Some practitioners may mistakenly believe that because a change is small, review requirements can be diminished. However, changes of all sizes require the same basic review process.

To ensure that the review process works, reviews are needed by individuals representing all disciplines associated with the change. To accomplish this goal, changes need to be screened to identify the impacted disciplines and the reviews need to be performed by qualified personnel.

Implementing systemic solutions that involve skilled specialists improves quality and takes the onus and liability off of the individual leading the change effort. A structured system empowers individuals who may be challenged by others to accelerate or minimize a review.

The MOC review is the sum of many reviews

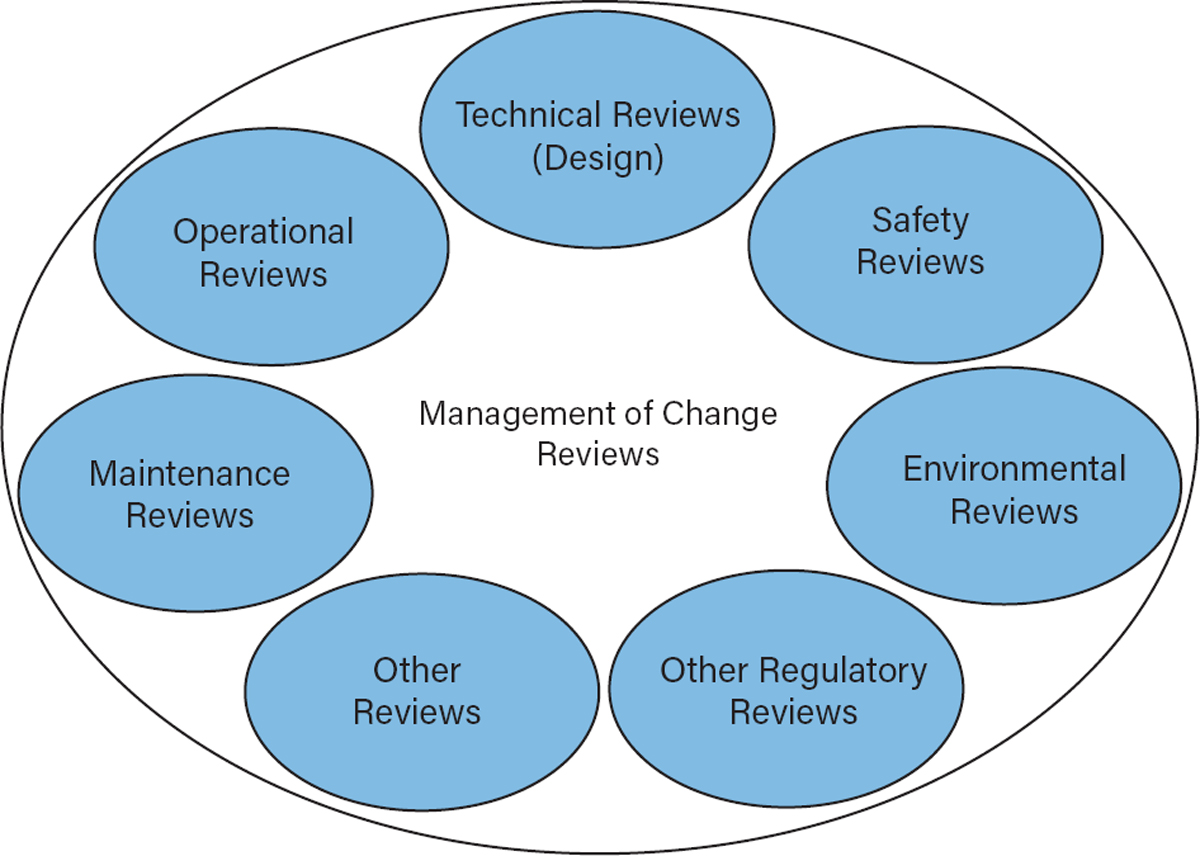

When discussing MOC, some people may refer to “the MOC review” as the mechanism for reviewing and approving changes. In fact, “the MOC” or the “MOC review” is the sum of many specific reviews (Figure 1). Those reviews include safety reviews, technical reviews, operational reviews, maintenance requirements reviews, and many more. A more detailed listing is shown as an example in Table 1.

▲Figure 1. Management of change (MOC) reviews consist of multiple discipline-specific reviews.

| Table 1. Management of change (MOC) reviews involve multiple discipline-specific reviews. This example lists typical reviews and provides suggestions on positional roles for screening and assessment. | |||||

| Management of Change (MOC) Reviews | Screening Done by: | Screening Approved by: | Review Facilitated* or Conducted by: | ||

| Project Lead | Project Lead | Discipline Group Rep. | Project Lead | Discipline Group Rep. | |

| Safety Reviews‡ | |||||

| Process Safety Reviews* | X† | X | X | ||

| Personal Safety Reviews | X | X | X | ||

| Technical Reviews‡ | X | X | |||

| Process Reviews | X | X | X | ||

| Mechanical Reviews | X | X | X | ||

| Rotating Equipment Reviews | X | X | |||

| Pump Reviews | X | X | X | ||

| Compressor Reviews | X | X | X | ||

| Turbine Reviews | X | X | X | ||

| Static Equipment Reviews | X | X | |||

| Plant/Field Piping Reviews | X | X | X | ||

| Pipeline Reviews | X | X | X | ||

| Pressure Vessel Reviews | X | X | X | ||

| Tank Reviews | X | X | X | ||

| Structural Reviews | X | X | X | ||

| Civil Reviews | X | X | X | ||

| Electrical Reviews | X | X | X | ||

| Instrumentation Reviews | X | X | X | ||

| Automation Reviews | X | X | X | ||

| Metallurgical/Corrosion Reviews | X | X | X | ||

| Other Technical | X | X | X | ||

| Maintenance Reviews‡ | X | X | X | ||

| Inspection | X | X | X | ||

| Testing | X | X | X | ||

| Predictive or Condition-Based | X | X | X | ||

| Preventive (Scheduled Replacement) | X | X | X | ||

| Operational Reviews‡ | X | X | X | ||

| Environmental Reviews | X | G | G | X | |

| Other Regulatory Reviews | X | G | G | X | |

| Other Reviews | X | X | X | ||

|

* Facilitated review with prescribed team members. † Process safety review screening will be more involved than other discipline screening. ‡ Referenced directly or indirectly in the U.S. OSHA PSM regulation (1). G = Seek guidance from group/department. |

|||||

Items in Table 1 with the ‡ symbol are either directly or indirectly referenced in the MOC or pre-startup safety review (PSSR) elements of the U.S. Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) regulation (1), but a more extensive set of specific reviews is needed to ensure that the change is assessed completely. Each company creates its own list of reviews that need to be considered for each change.

The screening step

Many changes will not involve all disciplines listed in Table 1; most small changes will only prompt several of these reviews. Therefore, a screening step is needed to determine which specific discipline reviews are relevant and which reviewers should be engaged.

Effective screening is essential. If the need for the review is not identified, the review will not happen. The initial screening step may be completed by a project lead or another person responsible for distributing the MOC to appropriate reviewers. Some disciplines that are impacted by the changes are self-evident. For example, changes to pumps, vessels, or electrical equipment would likely involve a pump or rotating equipment engineer, a static equipment or mechanical engineer, or an electrical engineer, respectively. Other discipline-specific specialists may also be qualified to conduct the review in place of an engineer. Company protocol will define those qualifications.

However, some discipline review needs are not as clear. For example, many environmental or regulatory review requirements may not be apparent without having the environmental or other relevant regulatory representative conduct the screening. Those initial screening reviews may need to be routed through the discipline specialist for approval. Those groups should provide guidance on how to determine when their department needs to be involved in the screening.

Because process safety is the core driver for the PSM regulation and because the need for process safety review may not be readily apparent, more rigor should be applied to process safety screening. A separate screening form can support the process safety screening effort, and the screening itself should be signed off by a skilled process safety practitioner.

Engage discipline representatives to perform discipline-specific reviews

Plant or site engineers are typically the jack-of-all-trades and the first engineering resource that operations will engage. These area engineers may manage multiple small projects and day-to-day issues. Operators, maintenance technicians, and field supervisory personnel need to understand the limitations of these plant engineers in performing discipline-specific assessments. Roles should be clearly defined by engineering management and communicated to the plant engineers as well as the operations and maintenance staff that these engineers support. Clarifying roles in this manner and stipulating requirements in procedures enables plant engineers to respond appropriately when the engineer may feel pressure to support their operations colleagues in moving ahead with what seems to be a simple change.

Finding qualified technical reviewers is a particular challenge for small companies not staffed with full departments that support various disciplines. Engaging outside or contract help, where needed, is important in these circumstances. For larger companies that have discipline-specific departments, engage these resources. Even if a site facility engineer has specific training or is professionally licensed in a given specialty, the engineer may not be privy to the latest discussions and decisions on technical topics within that group if he or she is not representing the discipline group at that time.

Example. A plant engineer supporting an oil and gas processing facility was the project lead for an MOC involving the temporary replacement of a piping section. The installation design included the use of a proprietary connector fitting — a mechanical part. As the project lead, the plant engineer was authorized to ensure that all technical, operational, safety, and regulatory reviews had been completed. As per company protocol, this change required mechanical engineering review. Although the plant engineer was a licensed mechanical engineer, by routing the MOC to the mechanical engineering group for review, the design was approved by personnel most familiar with the acceptable application of the device. Their involvement ensured that the installation conformed with service restrictions, the installation was properly coded and tracked, and the maximum service duration aligned with recent learnings.

Engage discipline representatives to support assessment of replacement-in-kind vs. MOC

A specialist may need to be engaged even before moving to MOC. In many cases, assessing whether a change meets the definition of replacement-in-kind (RIK) may require input from a discipline specialist. Manual valve replacements, component replacements, and transmitter replacements are examples of common changes where discipline specialists can best assess whether the replacement is RIK or not. The equipment design and component configuration, including materials and elastomers specifications, need to be fully evaluated to make this assessment.

Example. Instrumentation technicians were called out to address a series of leaks on several pressure transmitters that were recently replaced. The transmitters on a high-pressure gas injection header had been replaced due to obsolescence of the prior transmitters. Upon investigation, it was determined that the transmitters had been assumed to be RIK because they were scaled in the same operating range as the prior transmitters. However, the pressure rating for the body of the replacement transmitters had changed, so they were no longer RIK. A discipline specialist had not been involved in assessing whether the change was RIK or MOC.

Some plant engineers or other site generalists may not want to bother a specialist with what seems like a simple question. However, if it is a simple question, such as assessing whether a change is an RIK or a modification, the question should not take long to answer. Many discipline engineers would prefer to be brought in upfront to answer a simple question rather than discover an issue later or be brought in to help resolve a problem.

To enable complete, effective assessments, each review should be conducted by a qualified person representing each discipline. In many cases, it is also advisable to engage a specialist to assess whether changes meet the definition of RIK or not.

In praise of slow MOC: Be cognizant of the good-fast-cheap triangle

Many people are familiar with the good-fast-cheap triangle and its relationship to project management (Figure 2). The saying goes: “Pick two, you cannot get all three.” The other reality is that if you pull too hard on one corner, you may only get one.

▲Figure 2. The good-fast-cheap project management triangle highlights the give-and-take that occurs in quality, speed, and cost when progressing projects. Delivering all three is typically unachievable.

In considering this project management truth, it is worth remembering that one purpose of MOC is to slow down the process. Necessary reviews would not occur without the inherent slowing of the process that is facilitated by the MOC requirements. Good and cheap may be the best possible outcome. If in-house resources are not available, then the cost component may also be higher. Whenever possible, planning activities should build adequate review time into the schedules. When urgent action is needed, recognize the inherent risk that pulling on the fast side of the triangle introduces. Expedited reviews should emphasize completeness. One of the best tools to ensure completeness is to engage the proper reviewers.

Weighting the resources toward good — within the good-fast-cheap triangle — will best serve process safety.

In closing

To support an effective MOC process, use work processes that ensure thorough review by qualified representatives from all impacted groups and disciplines (e.g.,Table 1). In some instances, skilled personnel representing a given discipline may need to be involved in and approve the initial screening. Those specialists may also need to support the assessment of RIK vs. MOC. That means, don’t DIY your MOC! Engage discipline specialists to assess the change through their expert lenses.

Anecdote: Buyer Beware!

The tendency to minimize the need for specialist review happens in everyday life as well as work activities. The belief that small changes or upgrades need minimal review or that reviews only add cost and stand in the way of progress is a natural human perception. As an example, consider homeowners who decide to renovate their home taking a do-it-yourself (DIY) approach.

Homeowners often bypass the city or municipality permitting process to save time and money. And DIYers not only bypass this important review process, but they also pride themselves on doing the work themselves rather than calling in skilled and more costly contractors. The risks that stem from these decisions are typically not recognized or understood (2). If subsequent buyers are not savvy to these potential hazards, the future problems may be passed along to them.

Although MOC provides a framework for requirements in the workplace, the employees implementing those changes are susceptible to the same human biases and presumptions as the homeowners in this example. The MOC system of checks and balances needs to be consistently administered for changes of all sizes and complexity to ensure that risks are not introduced by small changes.

Literature Cited

- U.S. Occupational Safety and Health Administration, “Process Safety Management of Highly Hazardous Chemicals,” 29 CFR 1910.119, U.S. Dept. of Labor, Washington, DC (June 1, 1992).

- Weinberger, D., “What Happens If I Don’t Get a Permit for My Home Remodel?” Family Handyman, https://www.familyhandyman.com/article/remodeling-without-a-permit (May 25, 2022).

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.