Biomass pyrolysis yields undesirable hydrocarbons of high oxygen content. Because of the limitations inherent in current liquid hydrogenation technologies, the hydro-deoxygenation of these products is proposed to be accomplished using a catalytic membrane reactor. During preliminary trials with vegetable oils, an unexpected benefit was discovered, in that the system yielded much less trans fats in the end product.

The issue

Three-phase reactor systems have severe problems with low hydrogen solubility and catalyst particle boundary layer formation which leads to hydrogen starvation at the catalyst site. This hydrogen starvation yields poor reaction rates and undesirable by-products. Increasing temperatures for higher reaction rates only reduces solubility, and extremely high hydrogen pressures near 100 atm are often employed. Researchers at Kansas State are working on catalyst-coated membrane systems to avoid this starvation phenomenon.

The proposed system

The experimental concept called for use of asymmetric polymeric or ceramic membranes, permeable to hydrogen gas, like those used in gas separation or pervaporation applications. The membrane is then sputter or spin coated on the dense film or skin side with a platinum or palladium catalyst. The liquid reactants maintain contact with the catalyst at the surface but will not permeate the membrane. Hydrogen gas at reasonably low pressures (3 atm) is supplied to the (porous) support substrate side, where it permeates to the actual membrane. Once the hydrogen has diffused through the membrane to the catalyst surfaces, it dissociates on the surface and is available for reaction with the liquid. Gas solubility is never an issue, and catalyst coverage can be maintained at much lower pressures, with no hydrogen starvation resulting.

Experimental surrogates and surprises

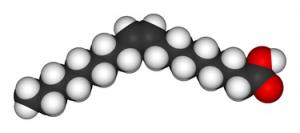

As a first test of feasibility of the proposed reaction system, the common process of hydrogenation of poly-unsaturated oils was used as a model. Current processes use a three-phase approach, and because of hydrogen starvation, they yield a "nasty" by-product: trans fats. It seems that if the catalytic site is not hydrogen saturated the cis-to-trans isomerization reaction occurs instead of hydrogenation of the double bond. In tests at KSU, common soybean oil (very high cis isomer unsaturation) was hydrogenated in the membrane reactor set-up, successfully demonstrating the process feasibility.

As a side benefit of the system, because of the more thorough hydrogen coverage at the catalytic site, much less isomerization occurred. Depending on the catalyst used, 48-58% less trans fats were created. That's good for a LOT of potato chips!

Additional tests and future work

Preliminary tests of "upgrading" high oxygen content bio-oils have been similarly successful. The membrane reactor allowed reaction temperatures several hundreds of degrees (C) lower and pressures an order of magnitude lower. Because of the very low surface area of the experimental set-up, conversion percentages were very low. New membrane set-ups are being designed to greatly increase the surface area, thus allowing much more effective conversion.

For more information contact Michael Wales, Ph.D. candidate, Kansas State University, Department of Chemical Engineering at mdwales@ksu.edu.